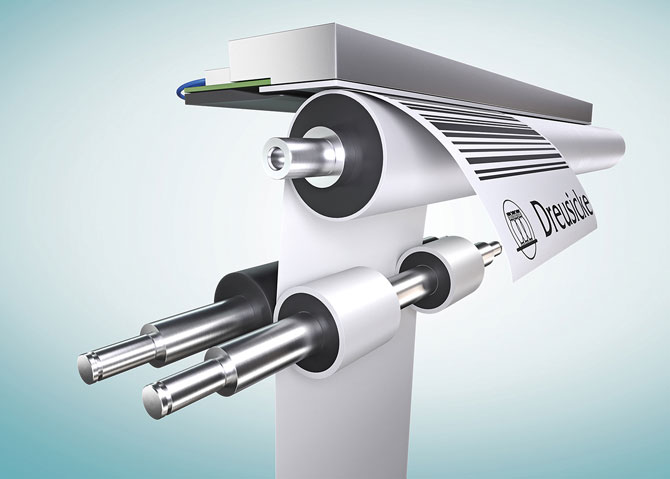

Platen Rollers for Thermal Printers

A high elasticity for a good pressure buildup, permanent heat stability of minimum 130°C and tight manufacturing tolerances including diameter, free run and cylindricity are just the basics of our specifically designed line of rubber roller coatings. A good grip guarantees a precise paper feed. The optimized compression reset behaviour helps to handle challenging applications as the use of different label widths. All rubber coatings are vulcanized directly onto the shaft to guarantee a homogenous distribution of pressure over the whole length of the platen roller against the printhead.

Antistatic Platen Rollers

Our antistatic rubber coatings for print and drive rollers help to prevent the buildup of elec-trostatic charge effectively.

Nonstick Platen Rollers for Linerless Labels

The ‚nonstick‘ ability of our platen rollers for linerless applications is inherent to the rubber coating. No extra surface-coating or long-chained oils are used to enhance this effect thus ensuring that nonstick properties remain constant during its lifetime use.

Drive Rollers

Highly abrasion resistant and yet with a good grip. Our rubber coatings for drive rollers are optimized for durability. By molding the rubber directly onto the shaft, a high torque can be transmitted. We take care of the whole drive roller assembly – as sourcing and assembling of bearings and pulleys.

Label Application Rollers

Manufactured from highly elastic cellular natural rubber. Roller-shaft and bearings are al-ready included in our standardized setup. Depending on your application we offer rollers in multiple hardnesses, diameters, lengths, and colors (standard is orange).